We use cookies to make your experience better. To helps us analyze data about web page traffic and improve our website, we need to ask for your consent to set the cookies.

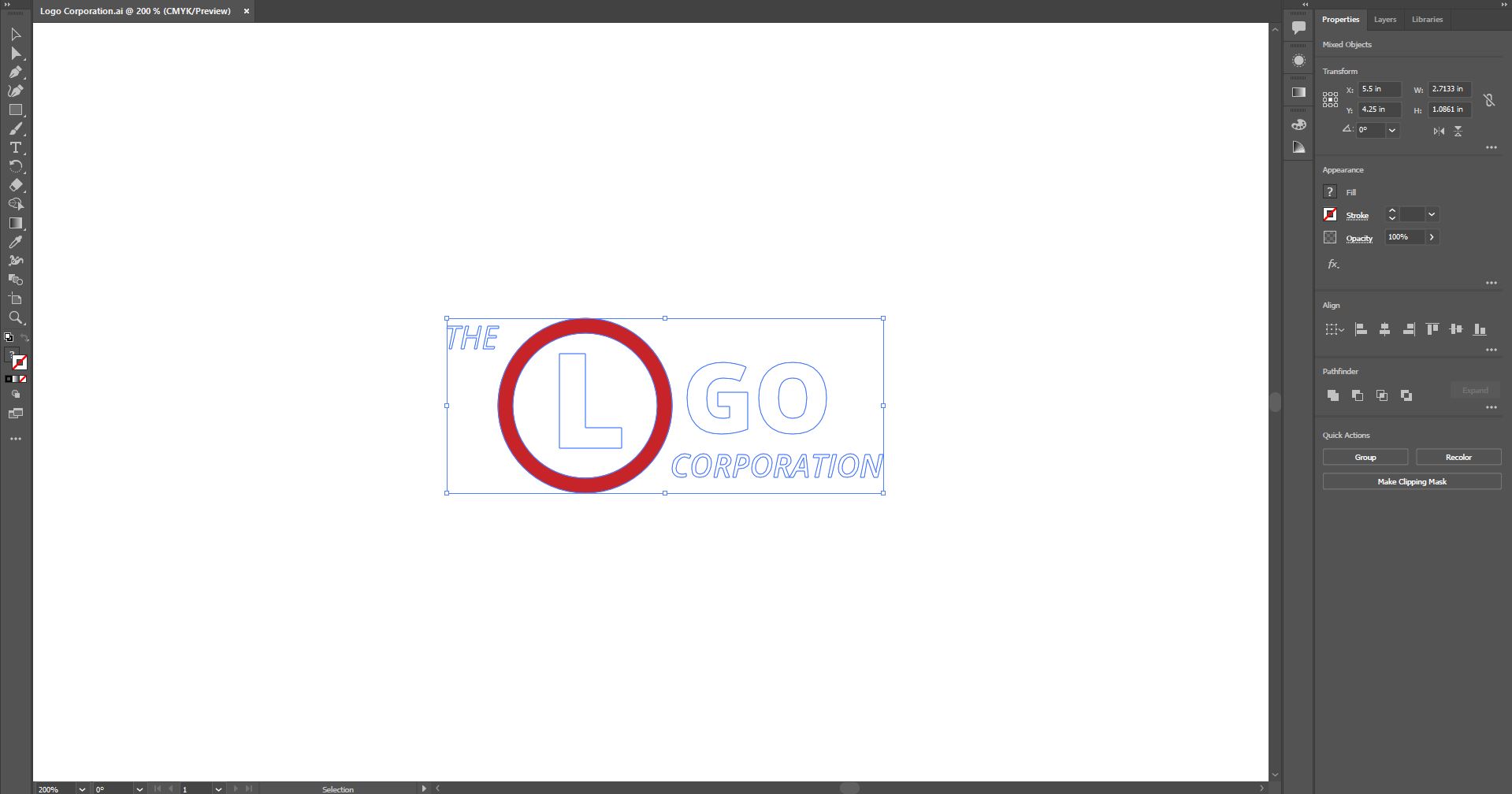

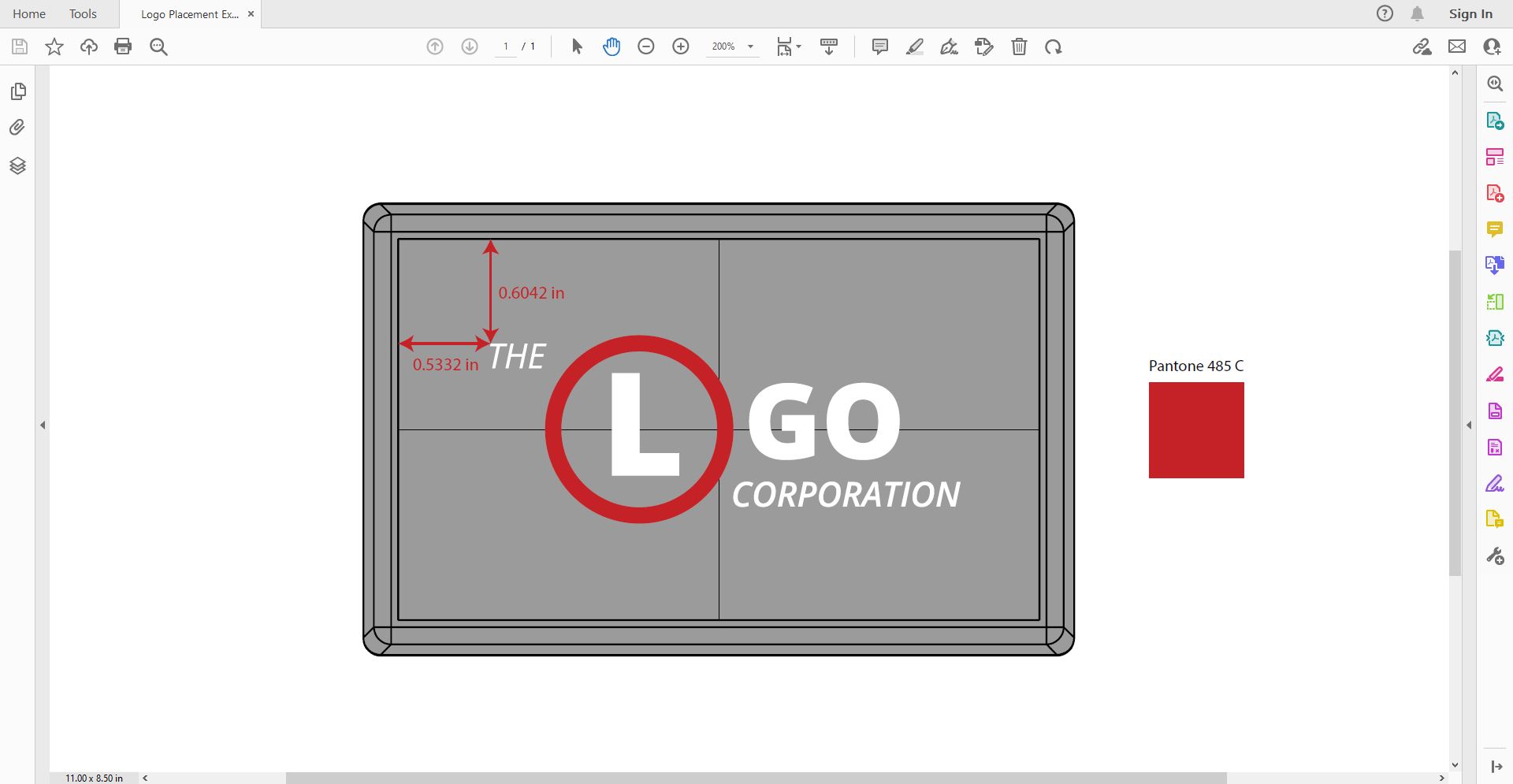

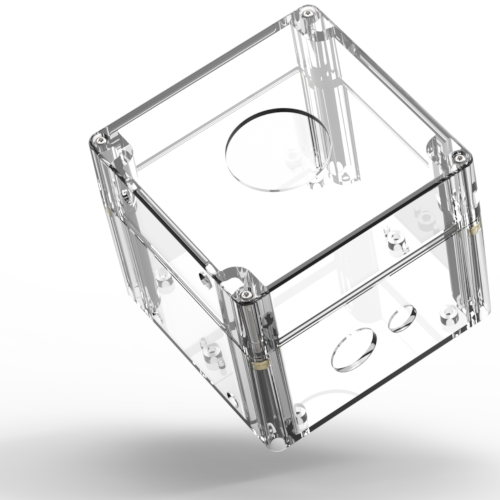

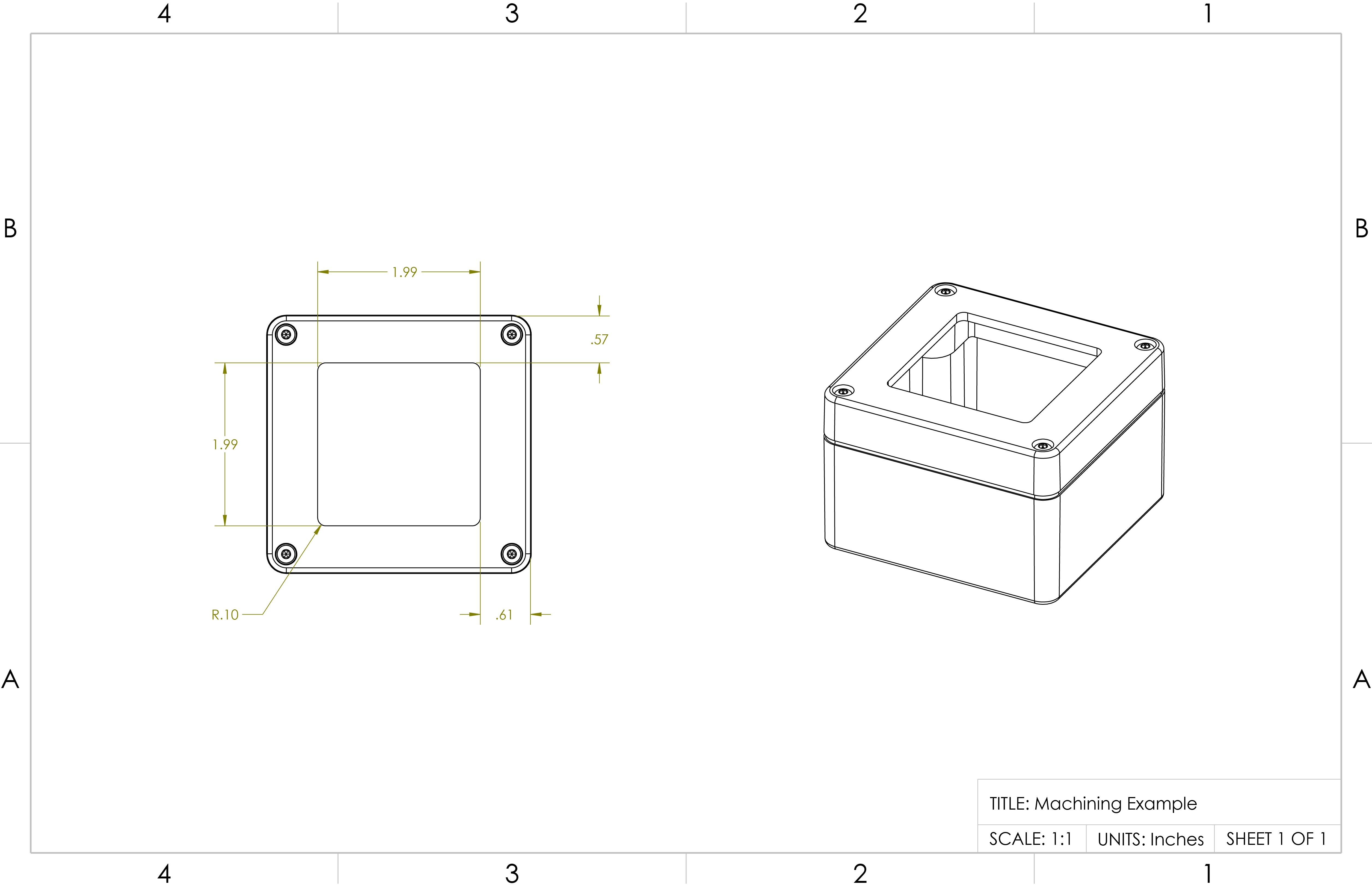

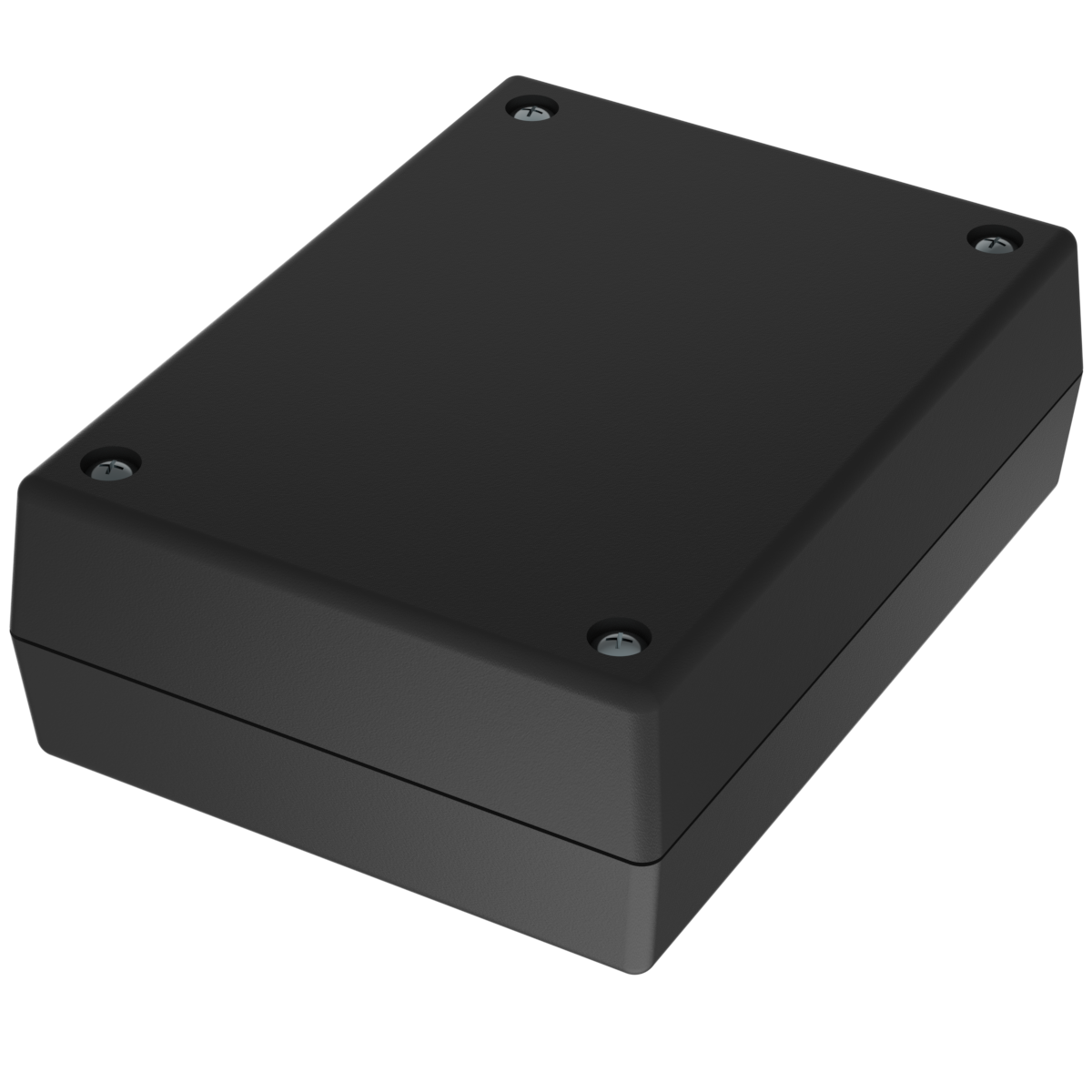

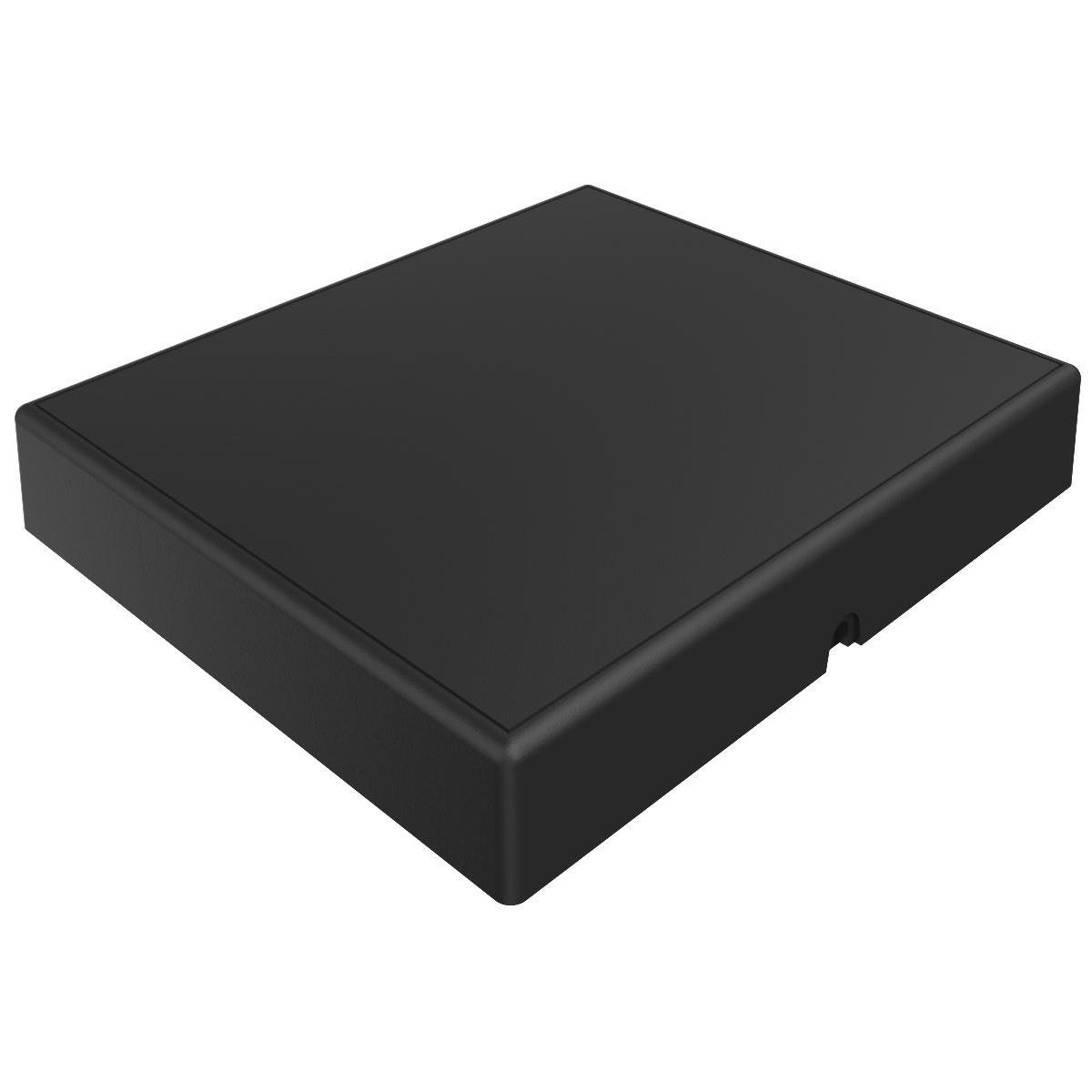

Serpac SE 1660 Black Hard Protective Case

-

$600.35

In stock

Only %1 left

SKU

SE1660

Write Your Own Comment

PDF

PDF